A truss is a fundamental structural element, composed of bars made of materials such as wood or steel, interconnected through flexible joints, forming triangular configurations that establish a robust framework. These formations play a crucial role in civil engineering, as they distribute loads and provide support in various contexts, including roofs, bridges, and other structures.

The connections binding these bars are created through welding or screw fastening at common points known as “nodes” or “reinforcement plates.” At these nodes, external forces are applied, and trusses have the ability to redistribute tension along the bars through axial forces acting in the direction of the longitudinal axis. This means that the bars within the truss can withstand both tensile and compressive forces, while bending forces are considered insignificant.

The strength of trusses lies in their triangular configuration and the distribution of loads axially throughout the system. Additionally, their feature of being lightweight adds to their appeal. These structures can be found in projects of colossal lengths, such as airport terminals, aircraft hangars, bridges, stadium roofs, auditoriums, and other entertainment-related buildings. Their ability to bear substantial loads and their efficiency make them essential elements in civil engineering.

Types of Trusses

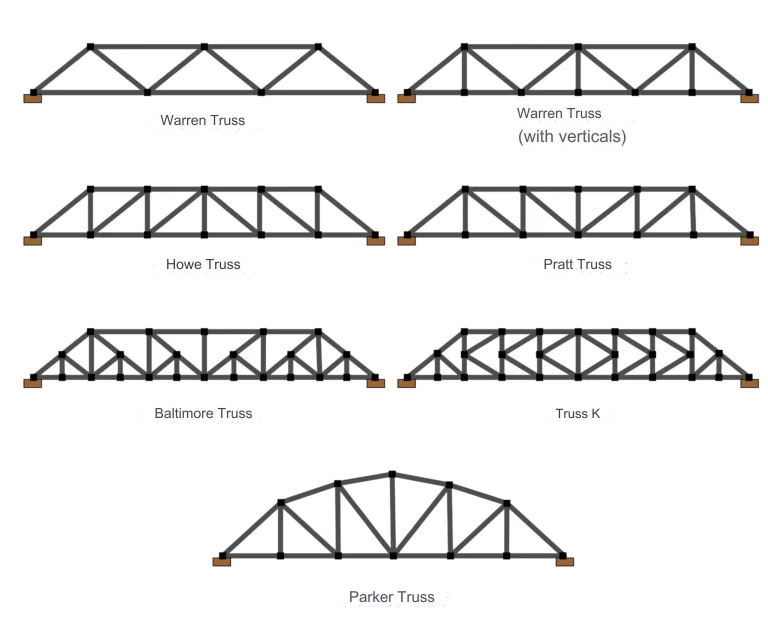

There are several widely recognized types of trusses used in civil engineering. Among these, Pratt, Howe, Warren, Parker, Baltimore, and K trusses stand out. Each has specific characteristics making them suitable for various applications in construction and structural design:

Pratt Trusses: characterized by diagonally inclined bars towards the ends and straight vertical bars, making them an optimal choice for bridge and roof construction.

Howe Trusses: composed of vertical and diagonal elements sloping towards the center. These trusses are especially suitable for supporting heavy loads and are used in building roofs.

Warren Trusses: composed of longitudinal bars connected only through angled transverse bars, forming equilateral triangles along their length. These trusses are ideal for medium-span bridges and roofs. There is a variant of Warren trusses incorporating vertical bars in the triangles to stabilize the horizontal members against buckling, especially when the upper horizontal bars would be too long and prone to buckling.

Parker Trusses: a variant of Pratt trusses, featuring a polygonal-shaped top bar.

Baltimore Trusses: considered a subclass of Pratt trusses, with additional reinforcements in the lower section of the truss to prevent buckling in compression bars and control deformation. They are mainly used in the construction of railway bridges, recognized for their simple yet highly robust design.

K Trusses: named for their structure forming the letter “K” due to the orientation of vertical posts and two oblique diagonals in each panel. These are a derivation of Parker trusses, which, in turn, originated from Pratt trusses. The main idea behind K trusses is to divide the vertical posts into smaller segments to reduce the risk of buckling, especially in compression posts. Despite their effectiveness, they did not gain widespread popularity due to their greater complexity compared to other designs.

Main Types of Trusses.

However, there is a wide variety of truss design variations, some of which may demonstrate greater efficiency than others. Despite these differences, all these variants share the fundamental mechanical principle in their operation.

Advantages of Trusses:

High strength and stability: Trusses are designed to effectively distribute loads along their members. Their triangular structure provides inherent resistance to compression and tension, making them exceptionally strong and stable. This makes them an ideal choice for supporting heavy loads in a variety of applications.

Lightweight: Despite their high strength, trusses are surprisingly lightweight compared to other structures, such as solid beams. This characteristic makes them ideal for projects where minimizing the dead load of the structure is desired, such as bridges and building roofs.

Design flexibility: Trusses are highly adaptable and can be designed to meet a wide range of structural and aesthetic requirements. Engineers can modify their geometry to meet the specific needs of a project, allowing them to be used in a variety of applications.

Efficient load distribution: Trusses evenly distribute loads along their members, minimizing the concentration of forces at individual points. This feature is especially useful in applications where an equitable distribution of loads is required, such as in the construction of suspension bridges or large-span roofs.

Ease of assembly: Trusses are often prefabricated in the factory and then assembled on the construction site. This simplifies the assembly process and reduces construction time compared to more complex structures. Prefabrication also allows for greater quality control.

Attractive aesthetics: Trusses have a distinctive appearance and are often considered aesthetically appealing. Their triangular geometry can add an interesting visual element to a structure, and they are often left exposed in architectural design to create a unique look.

Sustainability: Due to their lightweight and efficient load distribution, trusses can reduce the amount of materials needed for a construction project. This can lead to lower consumption of natural resources and a smaller carbon footprint, making them a more sustainable option compared to some heavier structures.

Parts of Trusses

Top chord: Set of inclined elements forming the top part of the structure, shaping the roof slopes or truss.

Bottom chord: Its main function is to support and transfer loads from the support points, connecting the lower end of the upper chords to prevent separation.

Pendulum: Vertical component establishing the connection between the strut and the tie, playing a crucial role in preventing buckling.

Diagonals: Inclined elements strategically arranged to connect the top chord to the tie, strengthening the structure.

Nodes: Critical points of the structure, usually made of steel plates, where the connection of all previously mentioned components takes place.

Parts of a Truss and details of a node.

Load Distribution

For the calculation of truss solicitations, we assume that uniformly distributed loads are divided in an idealized manner at the upper nodes in equal parts. Each truss system distributes loads differently, and it is the engineer’s job to determine the best option for the project.

Distribution of forces in a Warren Truss with verticals.

Conclusion

These structures play an essential role in the field of structural engineering, contributing significant value to a wide range of construction projects. Their presence is particularly notable in the design and construction of bridges, where their ability to efficiently distribute loads and provide strength is fundamental to ensuring the safety and durability of these critical infrastructures.

However, their influence is not limited to bridges, as trusses have also become a valuable option in the construction of buildings and vertical structures. Their ability to unify and stabilize a structure, resisting both tensile and compressive forces, has allowed architects and engineers to develop creative and functional designs that go beyond mere aesthetics.

Related

What are Sub-Drainage Works?

10 Things You Didn’t Know About Civil Engineering.

What is Moment of Inertia in Engineering?