Lightweight slabs or ribbed slabs are structural elements used in the construction of mezzanines and building roofs. Like solid slabs, they are made of reinforced concrete, with the distinctive feature of having ribs, also known as beams or formwork, incorporated into their design. These ribs are responsible for reducing the self-weight of the slab, thereby decreasing the load on columns and supporting walls. Essentially, lightweight slabs are a solution that enables the creation of lighter and more economical structures.

Lightweight slabs are an essential element in civil engineering that offers a range of advantages, from weight reduction to space efficiency. Their versatility makes them suitable for various applications in modern construction, making them a viable option for projects aiming to optimize resources and enhance structural efficiency.

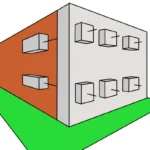

In the following image, the proper distribution function of a lightweight slab can be understood. A layer of concrete is left to handle compressive loads, and between one brick and another, another portion of reinforced concrete is left.

Functions of Lightweight Slabs

From a structural standpoint, lightweight slabs serve three specific functions:

- Transmitting the weight of finishes, their own weight, furniture, people, etc., to walls or beams.

- Transmitting seismic forces to walls.

- Connecting other structural elements (columns, beams, and walls) so that the entire structure works together as a single unit.

Advantages of Lightweight Slabs

Weight Reduction: The primary advantage of lightweight slabs is their ability to significantly reduce the structure’s weight. This not only decreases the amount of material required but also allows the construction of taller buildings without increasing the load on foundations.

Increased Space Efficiency: Being lighter enables the creation of more spacious and flexible interior spaces. This is especially beneficial in commercial and residential projects, where maximizing available space is crucial.

Lower Material Consumption: The reduction in material due to the incorporation of ribs leads to lower environmental impact and reduced construction costs.

Ease of Installation: Lightweight slabs are relatively easy to install, accelerating the construction process and reducing execution times.

Lightening Materials

Among the materials that can be used to lighten slabs are:

- Wood and Canvas: Involves constructing formwork using wooden boards and covering it with canvas to reduce leaks. Due to the materials used, it is not prone to reuse, as wooden boards often break during the concrete casting or curing process. This not only results in resource wastage but can also lead to deformations and significant errors in slab execution, negatively affecting project quality. Although the wood and canvas lightening method may be economically attractive, its limitations in terms of reuse, material fragility, and susceptibility to execution errors make it an unwise choice compared to other more effective and durable alternatives.

- Blocks: When opting for this lightening method, lightweight concrete blocks are commonly used. However, a disadvantage to consider is that these blocks remain inside the mezzanine, which, although to a lesser extent, still increases the structure’s weight.

- Polystyrene Formwork: colloquially known as “icopor” in Colombia, represents a highly convenient alternative for lightening slabs and is highly versatile to adapt to designer requirements. This material stands out as one of the most optimal options for slab lightening, as it can either remain embedded in the slab or be removed after the concrete has cured. Additionally, with proper handling, the formwork can be reused, adding a sustainability element to construction.

- Mold of Type M Formwork: This is the concave-type shell placed in a certain way to occupy a required volume in the slab. This form of formwork stands out as the most efficient, though also the most expensive, option for lightening slabs. Its construction is carried out with materials that facilitate installation, extraction, and the possibility of reuse in future projects. It is also important to note that, if the slab is to be left exposed, this type of formwork provides an exceptional aesthetic finish, enhancing the structure’s appearance.

Other Types of Lightweight Slabs

Two other widely used options are the steel deck system and beam-and-block slabs:

Steel deck

It is a versatile and efficient system for the construction of robust and lightweight mezzanines. This lightweight slab system is based on the use of grooved steel sheets as its main component. These sheets are designed to absorb tensile forces acting on the slab. On top of these sheets, a welded mesh is placed, and then concrete is poured to form the slab.

The steel deck system offers several significant advantages. Firstly, it is known for its quick installation, speeding up the construction process. Additionally, it provides excellent structural strength, making it suitable for a wide variety of construction projects. An additional advantage is that, during installation, the steel deck system can function as a working platform, further facilitating construction execution. Moreover, it eliminates the need for other types of formwork, simplifying the construction process and reducing costs.

Ribbed Slab with Beams and Blocks

It consists of supporting elements such as beams and lightening elements like blocks, along with welded mesh and a layer of compressive concrete. These elements are customized according to the dimensions required for the specific project. The beams are installed parallel to the supporting surface, and their ends rest on other materials, such as beams or other structural components, providing the necessary stability.

On the other hand, the blocks are elements designed to serve as permanent or dead formwork, meaning that once installed during construction, it is not possible to recover the material from the blocks after the concrete has cured. Therefore, these blocks remain in place throughout the construction and the building’s lifespan. It is crucial that lightweight materials, such as concrete blocks or polystyrene formwork, be used for the blocks, as their weight should not overload the structure.

Recommendations

When assembling a lightweight slab, meticulous attention is required in the construction process and the selection of the right materials.

- Avoid running pipes for hydrosanitary installations through the beams of the lightweight roof, flat or sloped beams, as they weaken them. If pipes must be placed in that position for any reason, they should be installed below the beams or the installation position should be modified.

- Use quality formwork to avoid deformations in the ribs that limit the purpose of the lightweight slab or adversely affect aesthetics.

- Design the slab correctly to prevent unwanted sinkings.

Related

What is Moment of Inertia in Engineering?

Reinforcement Steels

Metal Structures